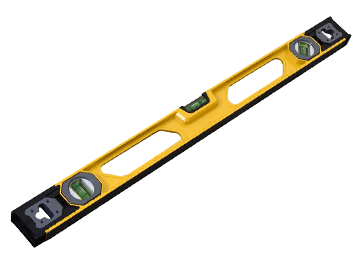

●Plastic spraying surface treatment ●Wall thickness 0.8 mm ●Better surface gloss and stronger ●180° 90° 45° 3 angles blisters ●High light transmittance, high definition level bubble ●Bottom with an in...

See DetailsImportance of calibration

Aluminum spirit levels undertake key positioning and correction tasks during the measurement process, and ensuring the accuracy of measurement results has a direct impact on construction and engineering quality. As the use time increases, the accuracy of the level may gradually decrease due to external impact, wear or environmental factors. Therefore, regular calibration of the aluminum spirit level is a necessary step to maintain its measurement accuracy, which can help to timely discover and correct errors and extend the service life of the instrument.

Methods and steps of calibration

The double-sided calibration method is usually used to calibrate the aluminum spirit level, that is, the level is placed on the measured plane, and after recording the measured value, the level is rotated 180 degrees and the value is recorded again. The difference between the two measurement results is used to judge the deviation of the instrument. If the deviation exceeds the allowable range, it needs to be adjusted or sent to a professional organization for calibration. The calibration process should be carried out in a stable, windless and vibration-free environment to ensure consistent measurement conditions. In addition, operations should be performed according to the calibration guidelines and parameters provided by the manufacturer to avoid errors caused by improper operation.

| Calibration and Maintenance Items | Main Content | Influencing Factors |

|---|---|---|

| Calibration Environment | Stable, windless, vibration-free | Environmental stability, operation compliance |

| Calibration Frequency | Multiple times initially, then once every six months to one year | Usage frequency, working environment |

| Maintenance Inspection Focus | Intact bubble tube, clear scale, tight connections, proper lubrication | Usage condition, maintenance thoroughness |

| Storage Conditions | Dry, avoid heavy pressure and impact | Storage environment, protective packaging |

| Professional Calibration Service | Standard equipment, certified qualifications | Institution qualifications, testing technology |

Impact of maintenance on accuracy

In addition to calibration, daily maintenance is equally important for maintaining the accuracy of aluminum spirit levels. Maintenance includes regular cleaning of the instrument surface, especially the bubble tube and scale part, to prevent dirt from affecting the reading. Avoid prolonged exposure to high temperature, humidity or strong sunlight to prevent material deformation or internal structure damage. Avoid falling or strong vibration during use to reduce mechanical stress. Proper storage in a special box to prevent dust and foreign matter from entering is also an important part of maintenance.

Calibration frequency and records

The calibration frequency should be determined according to the frequency of use and environmental conditions. It is generally recommended that newly purchased instruments be calibrated multiple times in a short period of time in the initial stage to ensure that the accuracy meets the requirements before use; under normal use, calibration should be performed once every six months or one year. If the working environment is relatively harsh, such as a construction site or a dusty outdoor environment, the calibration frequency should be appropriately increased. Detailed records should be kept after each calibration, including the calibration date, operator, instrument status and calibration results, for subsequent tracking and management.

Common calibration misunderstandings

Some users have misunderstandings when calibrating aluminum spirit levels, such as ignoring the influence of environmental factors or failing to strictly follow the steps, resulting in poor calibration results. In addition, the use of non-standard calibration methods or tools will also cause errors in the results. Do not dismantle the internal structure of the instrument for adjustment by yourself to avoid damaging the instrument function. If you encounter complex or unsolvable deviation problems, you should contact a professional testing and maintenance agency in time.

Key parts of maintenance inspection

In daily maintenance, you should focus on checking whether the bubble tube of the level is intact and there are no bubbles broken to ensure that the bubbles can accurately reflect the horizontal position. The scale lines on the surface of the instrument should be clear and intact to prevent reading errors. Connecting parts and screws should be tightened to prevent looseness from causing measurement deviations. Moving parts should be properly lubricated to ensure flexibility and accurate positioning. Regularly checking the status of all functional parts will help to detect potential problems in advance.

Maintenance tips and suggestions

The instrument should be cleaned in time after use to avoid residual dust and dirt clogging or wearing the bubble tube and scale. Avoid heavy pressure and impact when storing, and use special bags with buffer protection. For instruments that are not used for a long time, it is recommended to take them out for inspection and recalibration regularly to prevent performance from being affected by long-term static storage. Keeping the use environment dry and at a suitable temperature can also extend the service life of the instrument.

Selection of professional calibration services

When the user's own conditions cannot meet the calibration requirements, a professional metrology and testing agency can be selected to provide calibration services. These agencies have standardized equipment and technology, and can accurately detect and adjust instrument errors. When selecting an agency, attention should be paid to its qualification certification and service reputation to ensure the reliability of the calibration results. Professional calibration usually also provides calibration certificates to provide a basis for engineering quality management.